In the most general terms, drying is the use of heat to evaporate water from wastewater residual solids. The drying system, in addition to the dryer itself, generally consists of materials handling and storage equipment, heat generation and transfer equipment, air movement and distribution equipment, emissions control equipment, and ancillary systems. These equipment systems can take many forms, the details of which are beyond the scope of this paper. However, drying systems use different methods for heat transfer, including convection, conduction, and radiation heating. To some extent, multiple methods of heat transfer are used by individual systems, but they are generally categorized by their primary method of heat transfer.

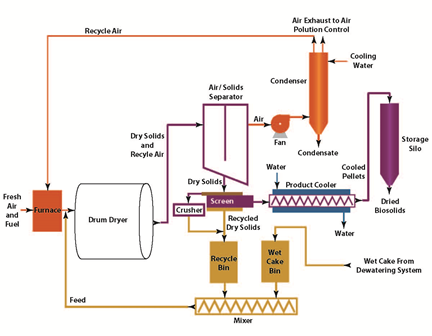

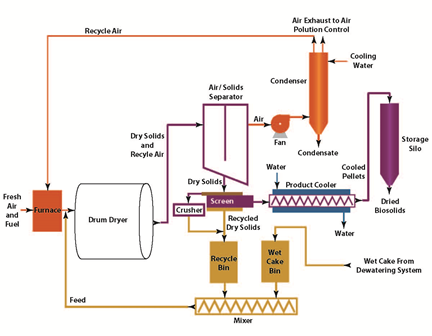

Systems that primarily use convection for heat transfer are often referred to as “direct” dryers. In direct heat dryers, hot air/gas flows through a process vessel and comes into direct contact with particles of wet solids. The contact between the hot air and cold wet cake allows the transfer of thermal energy, which causes an increase in wet cake temperature and evaporation of water. The hot air/gas can be produced by almost any source of heat, but most often is produced by a gas or oil-fired furnace. Examples of direct drying equipment are rotary drum dryers and belt dryers. A schematic diagram of a typical rotary drum drying system is shown in Figure 1.

Figure 1: Direct Type Rotary Drum Drying System

In this type of system, the heat supply is via a fuel-burning furnace that exhausts directly to the dryer drum. The dried material is separated from the warm exhaust gas and is then screened and processed for either recycling back to the dryer or routed to storage silos. The exhaust air/gas is cooled and part of it is recycled back to the dryer. The remainder of the air/gas is treated in air pollution control equipment and then vented to the atmosphere. Recirculation of the dryer exhaust accomplishes three important functions. First, it increases the overall thermal efficiency of the dryer system, second, it minimizes the volume of exhaust gas requiring air pollution control (APC), and third, it provides a safety feature by limiting the oxygen concentration in the system, which reduces the risk for explosions. APC systems for drum dryers typically consist of additional particulate removal followed by regenerative thermal oxidation to destroy odors and volatile organic compounds (VOCs). Other methods of APC, such as biofilters, are often used with different drying systems. Present day direct drying systems typically recirculate 70% to 90% of the dryer exhaust, thereby greatly reducing the size of the APC equipment. Direct drying systems vary considerably depending upon the type of equipment used to process the wet and the dried biosolids. Even rotary drum systems as shown in this figure vary considerably in general layout and the equipment used.

Another type of direct dryer that is seeing increased use in the U.S. and Europe is the belt dryer. This is typically a lower temperature system compared to a rotary drum system. The heat supply is usually a fuel-burning furnace, but in contrast to the rotary drum system, the system exchanges its heat to a thermal fluid, hot water or flue gas to air heat exchanger instead of the furnace exhausting directly into the dryer cabinet. The belt drying system distributes dewatered cake onto a slow moving belt, allowing for high surface area exposure to the hot air. Belt drying systems can utilize multiple belts to help minimize the size of the dryer cabinet. High dryer air recirculation (>90%) and low vent rates are common. Due to the gentle handling on the slow moving belts, dust generation within the dryer cabinet is low and the quantity of fines in the dried product should be low. Some belt drying technologies require dried product recycling to elevate the inlet solids composition to above the sticking point, while others inject dewatered sludge cake without additional recirculation equipment. The lower temperature belt drying system can more adequately utilize lower grade waste heat (in addition to high temperature waste heat).

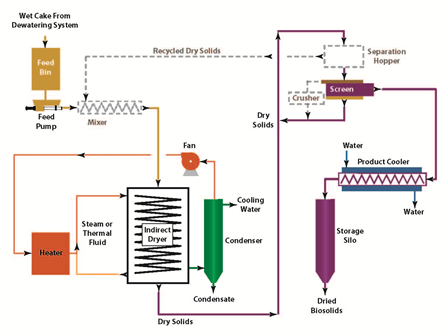

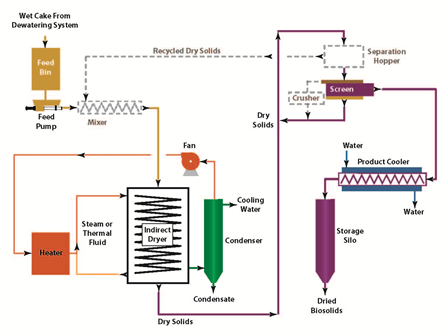

Systems that primarily use conduction for heat transfer are referred to as “indirect” dryers. With indirect dryers, solid metal walls separate the wet cake from the heat transfer medium (such as steam, hot water, or oil). Thermal energy is transferred from the heat transfer medium into the metal wall and then from the metal wall into the cold cake. The solids temperature is elevated by contact with hot metal surfaces and the solids never come in direct contact with the primary heating medium. Some types of indirect dryers do not require recycle of dried material, simplifying the system. Indirect thermal drying equipment includes paddle dryers with varying configurations, vertical tray dryers, and an indirect-type of fluidized bed dryer. A schematic diagram of a typical paddle drying system is shown in Figure 2.

Figure 2: Indirect Type Paddle Drying System

In this type of system, the heat supply is via a fuel-burning furnace that exhausts to a heat exchanger to heat oil, which is recirculated through the dryer. Steam, air, water, or other heat transfer fluids are other media that can be used. The solids are mechanically moved through the dryer and pick up heat from direct contact with the hot surfaces. Following the dryer, the material handling equipment is similar to that used in the direct system. In this system, the dryer exhaust primarily consists of water vapor and a small quantity of air which inadvertently enters the dryer with the wet feed. The exhaust from the dryer is sent to a condenser where the water vapor is condensed and sent back to the WWTP and the small air flow (containing some non-condensable organics) is then treated using various APC methods, depending on the system and supplier. For example, some systems send the exhaust to the furnace for use as combustion air, while others use a wet scrubbing system. Similar to direct drying systems, indirect systems also vary considerably in the type of equipment used to process the wet and dried material through the system (WEF MOP No. 8).

Solar drying systems rely on radiant energy from the sun. Dewatered solids are distributed into the greenhouse uniformly, either by automated mechanical means or by a manually operated tractor or truck. The sun’s radiant energy passes through the greenhouse enclosure (walls and roof) to heat and evaporate moisture from the sludge. The greenhouse enclosure prevents rain from adding water to the sludge and allows for a semi-controlled greenhouse environment, including air convection to help accelerate evaporation and enclosure of odors that can be processed through an odor control system. Solar drying systems are sensitive to local weather conditions, including solar radiation (considering typical cloud cover), relative humidity, temperature and wind speed and require thorough analysis during the design process. The solar drying system design will need to consider seasonality and historical weather data to ensure adequate design, and for some deviation from “average” weather years, some overdesign may be necessary. Solar drying processes are typically designed to provide solids compositions to exceed 75% dry solids, but can be difficult to sustain above 80-85%, depending on how loaded the system is. Solar drying systems typically provide a mechanical means for mixing and aerating the sludge periodically to promote the drying process. Solar drying is most viable in the southerly latitudes, for municipalities who have land available, and where snow cover is minimal. Radiant heat flooring can also be incorporated into the concrete greenhouse floor to reduce required greenhouse space and reduce the effects of weather variations to process performance. There are multiple solar drying systems available and vary in their equipment supply and how they operate.